A new interface developed by researchers in Bristol and Paris takes touch technology to the next level by providing an artificial skin-like membrane for augmenting interactive devices such a... Read more

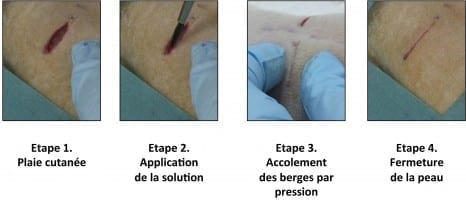

Innovative strategy to facilitate organ repair A significant breakthrough could revolutionize surgical practice and regenerative medicine. A team led by Ludwik Leibler from the Laboratoire M... Read more

This is the first time researchers have demonstrated reversible switching between static and dynamic self-assembly. Researchers from Aalto University and Paris Tech have placed water droplet... Read more

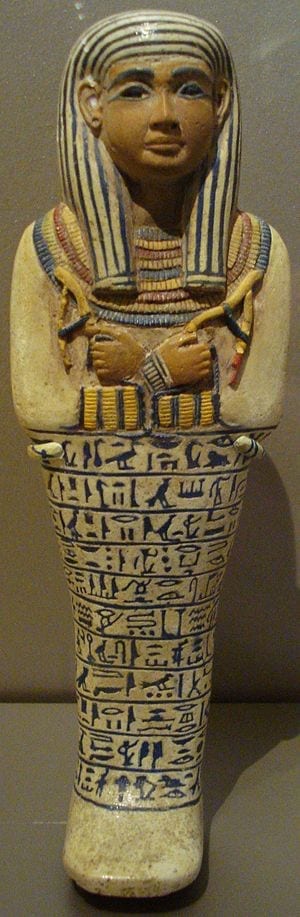

Video: Professor Stephen Hoskins shares more about the latest 3D printing methods in ceramics in this insightful interview. A 7,000 year old technique, known as Egyptian Paste (also known as... Read more