For the first time, the public has been treated to the spectacle of lab-grown meat cooked and eaten via live Webcast. Backed by Google billionaire Sergey Brin, Dutch tissue engineer Mark Pos... Read more

Stem cell science applications are almost unlimited Using human stem cells to tackle human health issues remains controversial in the United States, but a team of Dutch researchers ha... Read more

How much would you pay for a hamburger? How about US$345,000? No, it’s not wrapped in edible gold leaf and held together with a skewer made out of a diamond stick pin that you get to k... Read more

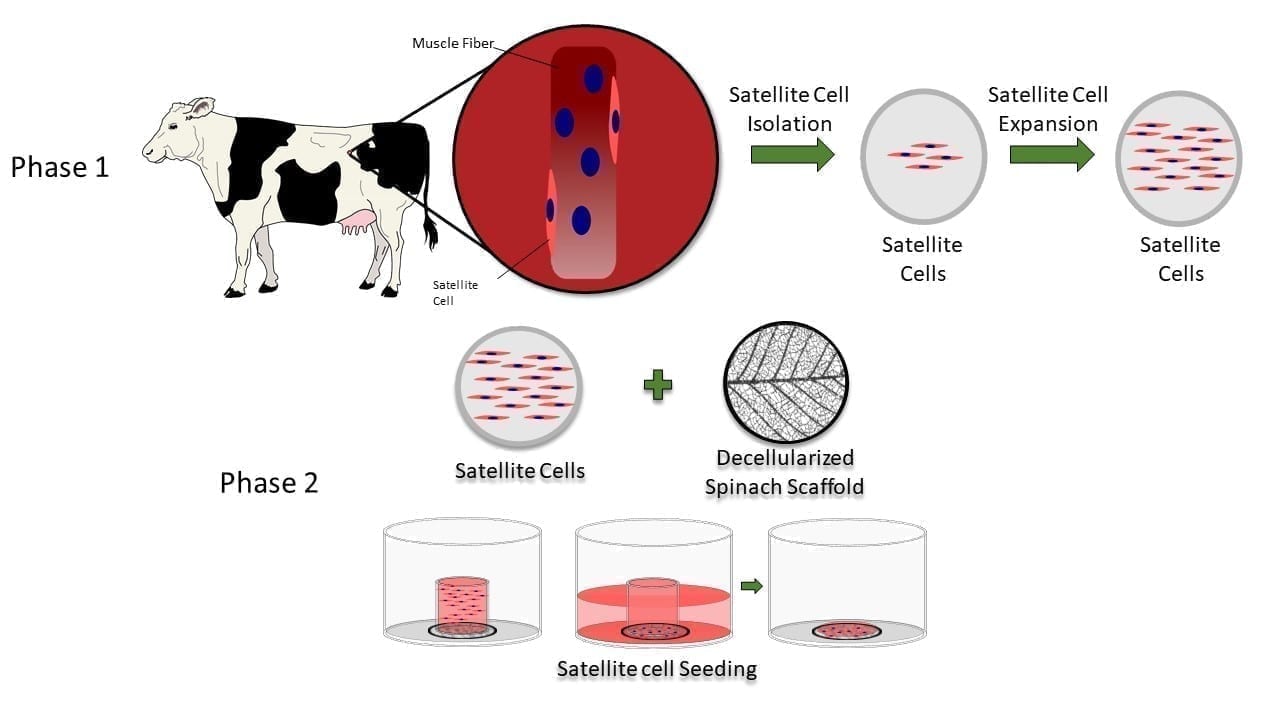

Scientists Initiate Action Plan to Advance Cultured Meat Late last week, an international group of scientists took a step closer to their goal to produce cultured meat. They agreed on import... Read more

Meat grown using tissue engineering techniques, so-called ‘cultured meat’, would generate up to 96% lower greenhouse gas emissions than conventionally produced meat, according to... Read more