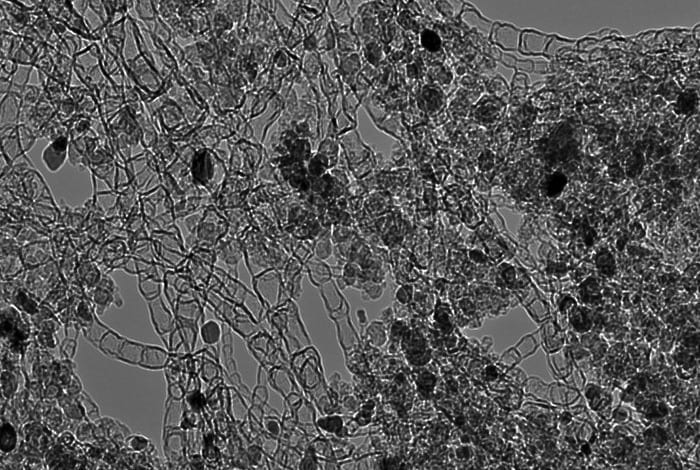

The disposal of used plastics – which are largely non-biodegradable – is a major environmental issue. ‘Bioplastics‘ that are naturally synthesized by mi... Read more

LATEST NEWS

- The Site is finally back and stable. Big changes in the wind . . . soon! Thanks for your patience and support!

Copyright 2024. Created by Innovation Toronto