Soon we will be able to replace fossil fuels with a carbon-neutral product created from solar energy, carbon dioxide and water. Researchers at Uppsala University have successfully produced m... Read more

A new discovery should make the alternative fuel butanol more attractive to the biofuel industry. University of Illinois scientist Hao Feng has found a way around the bottleneck that has fru... Read more

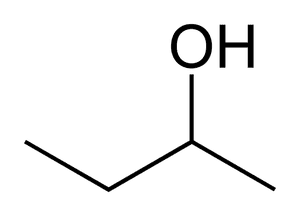

Butanol is particularly suited as a transport fuel A method developed at Aalto University in Finland makes it possible to use microbes to produce butanol suitable for biofuel and othe... Read more

Here’s one way that old-fashioned newsprint beats the Internet. Tulane University scientists have discovered a novel bacterial strain, dubbed “TU-103,” that can use paper t... Read more

A team of chemical engineers at the University of Arkansas has developed a method for converting common algae into butanol, a renewable fuel that can be used in existing combustible engines.... Read more