A replacement for oil has become a burning need in the 21st century A replacement for oil has become a burning need in the 21st century, with Prime Minister Benjamin Netanyahu having made it... Read more

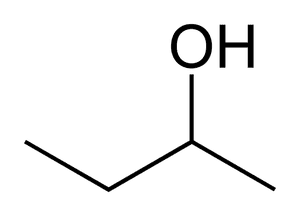

A new discovery should make the alternative fuel butanol more attractive to the biofuel industry. University of Illinois scientist Hao Feng has found a way around the bottleneck that has fru... Read more

We have the potential to use electricity as transportation fuel without needing to change current infrastructure Today, electrical energy generated by various methods is still difficult to s... Read more

Researchers from the University of Minnesota have announced a breakthrough in the quest to create a viable fuel alternative using greenhouse gases. The process uses two types of bacteria to... Read more

Ships powered by algae and planes flying on weeds: that's part of the future the U.S. Navy hopes to bring to fruition. Read more

For the past six years, the Los Angeles Auto Show has invited automobile designers to participate in its Design Challenges. The challenge for this year’s show was to come up with a design fo... Read more