via Churchill Lab

A new study by an international team of researchers led by the University of Minnesota highlights how manipulation of 2D materials could make our modern day devices faster, smaller, and better.

The findings are now online and will be published in Nature Materials, a leading scientific journal of materials science and engineering research.

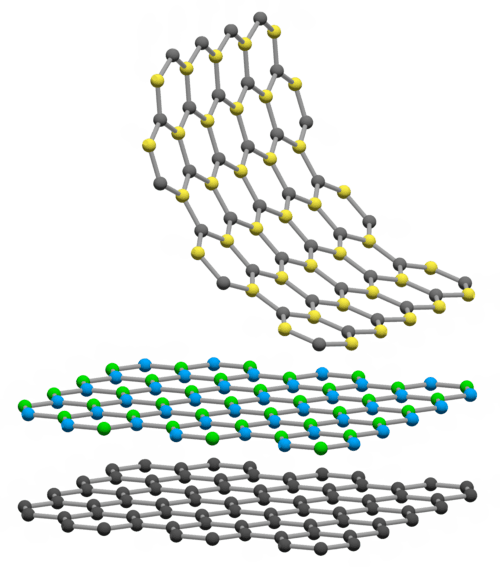

Two-dimensional materials are a class of nanomaterials that are only a few atoms in thickness. Electrons in these materials are free to move in the two-dimensional plane, but their restricted motion in the third direction is governed by quantum mechanics. Research on these nanomaterials is still in its infancy, but 2D materials such as graphene, transition metal dichalcogenides and black phosphorus have garnered tremendous attention from scientists and engineers for their amazing properties and potential to improve electronic and photonic devices.

In this study, researchers from the University of Minnesota, MIT, Stanford, U.S. Naval Research Laboratory, IBM, and universities in Brazil, UK and Spain, teamed up to examine the optical properties of several dozens of 2D materials. The goal of the paper is to unify understanding of light-matter interactions in these materials among researchers and explore new possibilities for future research.

They discuss how polaritons, a class of quasiparticles formed through the coupling of photons with electric charge dipoles in solid, allow researchers to marry the speed of photon light particles and the small size of electrons.

“With our devices, we want speed, efficiency, and we want small. Polaritons could offer the answer,” said Tony Low, a University of Minnesota electrical and computer engineering assistant professor and lead author of the study.

By exciting the polaritons in 2D materials, electromagnetic energy can be focused down to a volume a million times smaller compared to when its propagating in free space.

“Layered two-dimensional materials have emerged as a fantastic toolbox for nano-photonics and nano-optoelectronics, providing tailored design and tunability for properties that are not possible to realize with conventional materials,” said Frank Koppens, group leader at the Institute of Photonic Sciences at Barcelona, Spain, and co-author of the study. “This will offer tremendous opportunities for applications.”

Others on the team from private industry also recognize the potential in practical applications.

“The study of the plasmon-polaritons in two-dimensions is not only a fascinating research subject, but also offers possibilities for important technological applications,” said Phaedon Avoruris, IBM Fellow at the IBM T. J. Watson Research Center and co-author of the study. “For example, an atomic layer material like graphene extends the field of plasmonics to the infrared and terahertz regions of the electromagnetic spectrum allowing unique applications ranging from sensing and fingerprinting minute amounts of biomolecules, to applications in optical communications, energy harvesting and security imaging.”

The new study also examined the possibilities of combining 2D materials. Researchers point out that every 2D material has advantages and disadvantages. Combining these materials create new materials that may have the best qualities of both.

“Every time we look at a new material, we find something new,” Low said. “Graphene is often considered a ‘wonder’ material, but combining it with another material may make it even better for a wide variety of applications.”

Learn more: Researchers Explore New 2D Materials That Could Make Devices Faster, Smaller, And Efficient

The Latest on: Polaritons

[google_news title=”” keyword=”Polaritons” num_posts=”10″ blurb_length=”0″ show_thumb=”left”]

via Google News

The Latest on: Polaritons

- Polaritons articles from across Nature Portfolioon April 22, 2024 at 4:59 pm

Polaritons are hybrid particles made up of a photon strongly coupled to an electric dipole. Examples of such a dipole include an electron–hole pair in a semiconductor, which forms an exciton ...

- Nanotechnology Newson April 9, 2024 at 5:00 pm

Apr. 16, 2024 — Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that could make ... A Single Atom Layer of Gold ...

- Electrically Controlled Polaritons Illuminate Next-Gen Displayson April 9, 2024 at 7:23 am

Their achievement represents the world's first successful instance of electrically controlling polaritons—hybridized light-matter particles—at room temperature. Polaritons are hybrid particles ...

- Research team exerts electrical control over polaritons, hybridized light-matter particles, at room temperatureon April 9, 2024 at 6:41 am

Their breakthrough marks the world's first instance of electrically controlling polaritons—hybridized light-matter particles—at room temperature. The research has been published in Physical ...

- Breakthrough achieves electrically controlled polaritons at room temperatureon April 8, 2024 at 5:00 pm

Their breakthrough marks the world's first instance of electrically controlling polaritons – hybridized light-matter particles – at room temperature. This research has been published in Physical ...

- Will the convergence of light and matter in Janus particles transcend performance limitations in the optical display industry?on April 7, 2024 at 5:00 pm

Team successfully exerted electrical control over polaritons, hybridized light-matter particles, at room temperature. A research team consisting of Professor Kyoung-Duck Park and Hyeongwoo Lee, an ...

- Optically trapped quantum droplets of light can bind together to form macroscopic complexeson March 6, 2024 at 4:00 pm

In 2006 a new platform emerged with the demonstration of macroscopically coherent quantum fluids of exciton-polaritons to explore many-body quantum phenomena through optical techniques.

- the ultra-high-resolution imaging of the image phonon-polaritons in hBN launched by the gold crystal edge (IMAGE)on July 13, 2022 at 11:00 am

Nano-tip is used for the ultra-high-resolution imaging of the image phonon-polaritons in hBN launched by the gold crystal edge Disclaimer: AAAS and EurekAlert! are not responsible for the accuracy ...

- Metamaterials and Metasurfaces: Engineered Structures Revolutionizing Light and Matter Interactionson August 18, 2020 at 1:09 pm

The superlens concept relies on the generation of surface plasmon polaritons enhancing the evanescent fields to restore the near-field components of the Fourier decomposition of the source object, ...

via Bing News